CAD

Services

Creating 3D versions of concepts while maintaining the original essence of the design is tricky business. An eye for subtleties and design are crucial in developing manufactured parts that reflect the original intent.

Modeling services:

- SolidWorks & Creo models and assemblies

- Complex surfaces including splines and organic shapes

- Moving parts, mechanisms, sub assemblies

- Robust models for easy updating

- 2D drawings for tooling

Concept

Services

Designs should reflect their appropriate markets and industries. Fancy curves and lights may be great for a consumer level part, but may look out of place in an industrial setting. While it may seem that looks are largely subject to taste, large groups tend to gravitate toward attractive designs independently.

Design Services:

- Many sketches showing different design directions while maintaining industry and brand appropriateness

- Designs that fit in with existing product lines

- New or updated product lines

- refinement sketches to dial in specific details

- Colored renderings for selection and presentation

- Scale mockups and models

- Quick CAD concepts and models for validation

Design for Manufacture

Services

We design products for the real world. That idea permeates every phase of the project from sketching through production. Our concepts and parts are generated from the ground up to be manufactured with the appropriate process and cost target.

Manufacture Targeted Design:

- Expert in manufacturing processes

- Bill of Materials for OEM/Custom parts

- 2D Drawings for manufacture

- Cost reductions during development

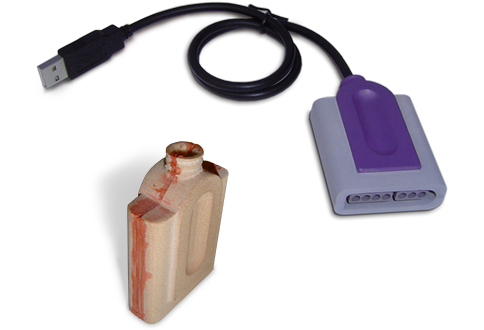

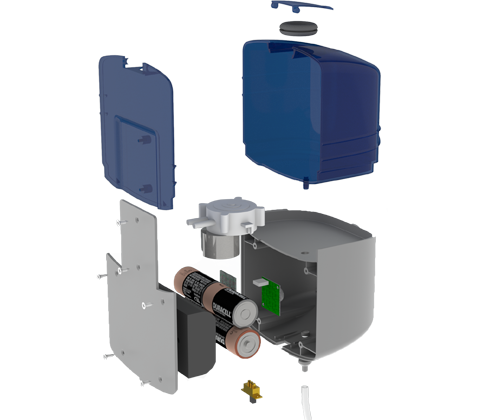

Prototype and Manufacture

Services

Prototypes are made during the design process to help verify and test parts and aesthetics. They can be printed in 3D off a developed CAD model, or built to spec from local manufactures. The type of material and process used depends on the design, schedule, and application. Once a design has been validated, the product is ready for production.

Prototyping services:

- 3D Printed ABS plastic

- Hand shaped urethane foam

- Foamboard construction

- Working mechanical prototypes through local machine shops and vendors.

Support through manufacturing:

- Drawings and models needed to quote and produce parts

- Changes and updates to the tool as required by vendor