ABS

Uses: Enclosures, Consumer Products

- Wide temperature rating (Use between -4°—176°F / -20°—80°C)

- Good for injection molding

- Good plating & painting characteristics

- Many colors available

Polycarbonate

Uses: Electronic housings, Lenses, Medical

- High temperature rating (Softens at 311°F / 155°C)

- Strong impact resistance

- Good coloring options, including clear

- Glass filled for extra strength

Polyurethane

Uses: Industrial Housings,

Foam Padding, footwear

- 2 Part thermoset

- Flexible or rigid

- Low Pressure Forming, Reaction Injection Molding (RIM)

- Can be machined or sanded for modeling

Elastomers

Uses: Flexible Handles and

Shock Absorption

- Multiple material types

- Wide range of Flexibility

- Can be overmolded around plastic components

- Some color and design restrictions

Polypropylene

Uses: Hinges, Flexible Parts

- Create Living Hinges

- High temperature rating (Melting point: 320 °F / 160 °C)

- Higher performance than polyethylene

Polystyrene

Uses: Packaging & Faceplates

- Wide Range of Color options, including clear

- Low Melting Point (Softens at 150°F / 70°C)

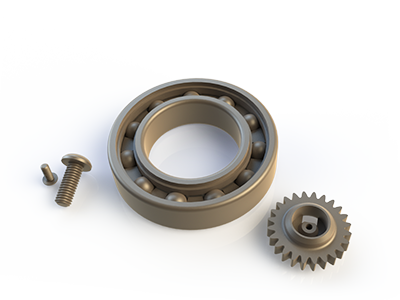

Polysulfone / PEEK

Uses: Medical Products, bearings, fasteners

- High temperature rating (Softens at 289°F / 143°C)

- Transparent

- Can be glass reinforced

Other Resources

Additional Plastics

- Resins

- Non petroleum plastics

- Composites

- Renewables